The first step is to remove all the grass, plants, trees, stumps, leaves, and other organic material from where the home will be placed for at least 10’ around the home. If the top layer of soil contains soft, silty clay or rich topsoil, then it too must be removed. These types of soils do not provide adequate drainage and/or support.

Types of Soil

Clay (Good)

Clay is typically yellow, red, or bluish-gray. When combined with water, clay exhibits considerable strength when air-dry.

Silt (Bad)

Silt contains fine sand and/or other material carried by running water and deposited as a sediment. Silt exhibits little or no strength when air-dry.

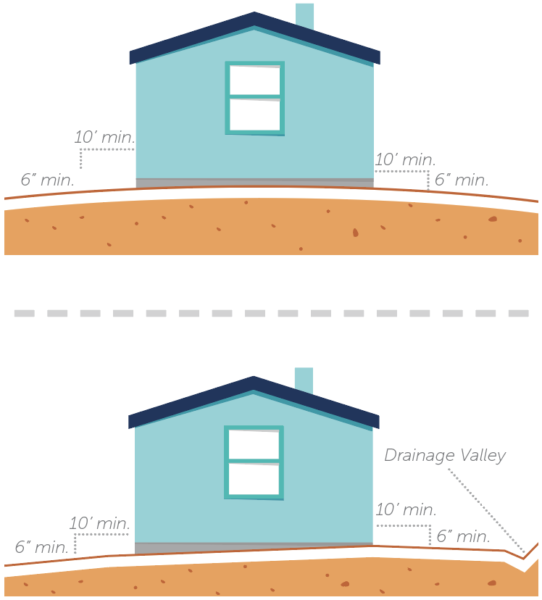

After removing the vegetation and unsuitable soil you must crown the home site so that the area under the home slopes away from the center. The slope should maintain a minimum of 5-6 inches of fall per 10 feet starting two feet under the home and extending 10 feet away from the home’s perimeter. Best practice is to ensure the entire area under the home drains to the exterior.

Crowning the site can be achieved by cutting the site down or building the site up. Cutting the site down is the fastest and least expensive method. Simply push the dirt away to achieve the required slope, hauling away or redistributing removed soil. If the site does not allow cutting the slope, then you will be required to build up the site. This must be done with controlled fill. “Controlled fill” is high-quality medium to hard clay or sandy gravel with no construction debris, organic material, or large rocks mixed in. The site must be built up in 4- to 6-inch increments, and each layer must be compacted.

THE PROFESSIONAL WAY

To preserve the integrity of your foundation, always backfill around all piers so no standing water can collect on or around footers and install an approved vapor barrier. Finally, install gutters with a minimum 6’ extension on each downspout, directing water away from the home.

Properly Graded Home Sites

Compacting Soils

To perform well, structures must be built on firm soil. Most soil contains pockets that are filled with either air or water that can cause settling when compressed. Poor compaction may cause a foundation to fail. The failure may take place immediately or it may occur weeks, months, or even years after construction.

A sheepsfoot roller is the best tool for compacting soil. The proper compaction of soil is heavily dependent on the correct moisture content. Water may be added to increase the moisture content or the soil may be aerated with a disc to dry it. After the correct moisture content has been obtained, compaction with a sheepsfoot roller becomes the simple act of forcing out the air pockets which naturally occur.

During the first pass of a sheepsfoot roller, the feet punch full depth into the soil (upper drawing). With subsequent passes, compaction strengthens the soil and the feet don’t penetrate as deeply (lower drawing). When the roller walks out of the fill, adequate compaction is indicated. The first compacted layer is the most important. Compaction can’t be accomplished on top of a spongy layer of soil. There must be a base to compact against. Therefore, it’s necessary to strip down to sound material before beginning to compact fill.

When compacting a large area of fill, the soil should be spread in 6- to 8-inch lifts so that the finished compacted layer will be 4- to 6-inch thick. Soil cannot be properly compacted into lifts thicker than 6 inches. If soil isbeing compacted with a sheepsfoot roller, proper compaction should be achieved with 12 passes.

Other Methods for Compacting Clay

Heavy rubber-tired equipment generally is not as effective as a sheepsfoot roller. Compaction occurs only under the wide tires. To achieve what 12 passes of the sheepsfoot roller will accomplish requires at least 24 properly routed passes of large-tired equipment. It is virtually impossible to control individual passes so that they follow the wheel paths of the previous pass or correctly distribute the compaction effort.

*This content contains excerpts from “Methods for Achieving & Measuring Soil Compaction” by Norbert 0. Schmidt, University of Missouri-Rolla, and Charles 0. Riggs, Central Mine Equipment Company in St. Louis, Missouri. This article was first published in Concrete Construction magazine, a publication of Hanley Wood Business Media. It is reproduced here with permission.